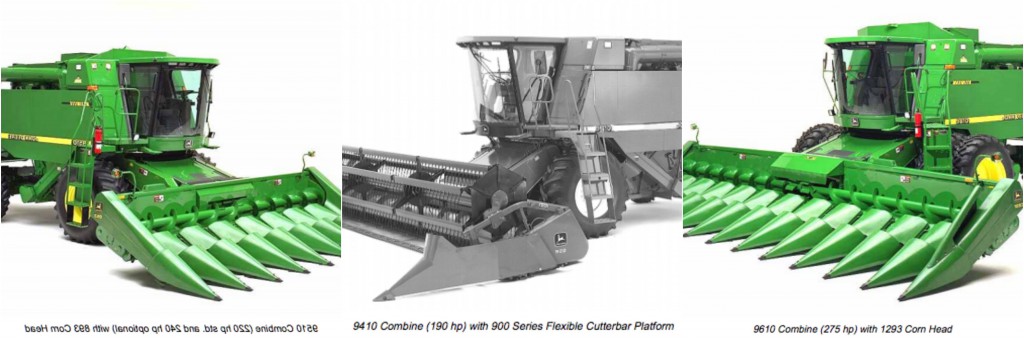

Three models of the John Deere 10 Series Combines are available to harvest all types of crops across a wide range of field conditions. All three models (9410, 9510 and 9610) have a variety of features for better performance, safety, service and reliability to make harvesting and grain handling easier for farmers.

Some key features include Sound-Gard™ styled cabs, electro-hydraulic controls, hydrostatic ground drive systems, feederhouse reversers, Quadra-Flo Plus™ cleaning systems, durable final drives, large flip-open side shields and more.

We thought it would be helpful to better explain some of the functions that apply specifically to grain handling operations. So, here’s a brief overview of the key features of the legacy John Deere 9410, 9510 and 9610 combines that we think are most important to grain handling:

Clean Grain Elevator

- Columns of grain can be handled by the elevator without plugging

- More belt wrap from large drive sheaves allow more capacity in the clean grain elevator system

- Allows you to start a full elevator without fear of drive belt slippage or elevator plugging

- More productively and efficiently delivers clean grain to the grain tank

- Elevator chain tension can be easily adjusted from the ground

- Heavy-duty horizontal and vertical grain tank unloading augers

- Grain tank floor components in high wear areas, grain tank cross auger covers

- Slower speed, heavy duty unloading auger drives

- Stainless steel grain tank floor components and clean grain elevator

Tailings Return Elevator

- Lower auger with a deep trough to move returns gently into return elevator

- Reduces potential for tailings plugging and improves grain quality

- Deep sump-type tailings return elevator assures rapid movement of material even with the heavier returns experienced when chaffer fingers are removed for side slope operation

- Sump-type elevator eliminates force-feeding of grain from return auger into return elevator

- Chain tension can be quickly and easily adjusted by two draw bolts located at ground level

- Hinged door allows complete and convenient grain cleanout

- Inspection is safely and conveniently performed from operator’s ladder landing through an easy access door

Grain Tank Loading Auger

- Assures rapid movement of grain from clean grain elevator into the grain tank

- Long auger to avoid push against large volumes of grain when filling the tank, contributing to better grain quality

- Upper end of loading auger has heat-treated, double thick auger flighting to assure longer wear life in abrasive crop conditions

- Easily removal auger to reduce overall combine height for storage

- Gear box is housed in a heavy aluminum case with a stainless steel cover to protect gear case from wear in abrasive crops

- Gears immersed in oil for more constant lubrication

Large Grain Tank & Fast Unloading System

- Full grain tank helps detect full grain tank on side slopes

- Large window provides better visibility of grain in tank from the cab

- Hinged window to allow for cleaning and easy access to rear cab window

- Convenient, hinged door panel provides quick access to obtain a grain sample

- Grain trough delivers grain right to sampling area for increased safety

- Grain tank has minimal flat ledges and surfaces to hold grain for easier cleanout

- Unloading auger positioned up high to provide ample clearance into large grain trucks or carts, and swings full 105 degrees to easily top off grain trucks or carts.

Hopefully this provided you with a solid understanding of the features incorporated in 9410, 9510 and 9610 John Deere combine models that were designed to make grain handling easier, more productive and efficient.