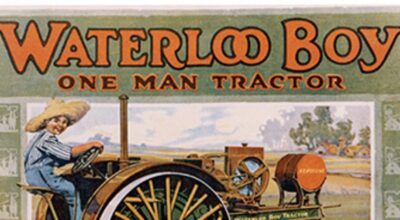

John Deere has always been a leader within the agricultural industry, with tractors being one of its specialties. This is in part due to Deere’s acquisition of the Waterloo Gasoline Engine Company back in 1918, which helped lay the groundwork for the development of its first all-wheel-drive tractor model. However, the tractor was still an advanced concept when Deere initially acquired Waterloo, meaning there would be a learning curve that the company needed to surpass in order to succeed.

Despite the fact that the John Deere Waterloo Boy tractor debuted in Kansas in 1918, it wasn’t until 1920 that the two brands truly came together. Deere needed to fine-tune the look and feel of the Waterloo Boy first, debuting its leaping deer logo to establish its brand within the tractor itself.

Since then, Deere has come a long way, defining itself as one of the leading tractor providers in the industry. Let’s take a look at how tractors are made today at John Deere’s largest global manufacturing complex: Waterloo Works.

https://www.youtube.com/watch?v=MGQJn_v-pAs

Continuing the Deere Legacy Today

Deere has now been in business for more than 100 years and from Day One, it has always been about exceeding customer expectations. Today, Waterloo Works specializes in the company’s 7R, 8R, and 9R Series tractors to ensure that each machine is as reliable as it is efficient. Deere is constantly refining its technologies and improving its large tractors to prove that performance pays.

Its factory line at Waterloo is devoted to meeting and exceeding the industry’s highest standards. The complex itself is completely modernized, which allows workers to complete complex castings with tight tolerance to meet the size of each tractor. Deere is also the only agricultural manufacturer in the country with its own foundry, enabling more control over the methodology used to meet customers’ high standards.

Furthermore, x-ray displays help workers check castings for complete accuracy and density. Products are also put through rigorous testing before they make their way to the customer to ensure that everything operates accordingly. If the process is not done correctly, the line stops until everything is corrected – Deere never settles for less.

All down the line, several tests are performed and there are checkpoints for each tractor. Samples of tractors are also taken every month for 20 hours of shakedown testing, where machinery is tested at real-world sites.

For more than a century, Deere has been consistently improving, enhancing, and refining its tractors, and the work continues today.

If you have any questions about Deere tractors, you can contact your local John Deere dealer.

If you enjoyed this post or want to read others, feel free to connect with us on Facebook, Pinterest, or Twitter!