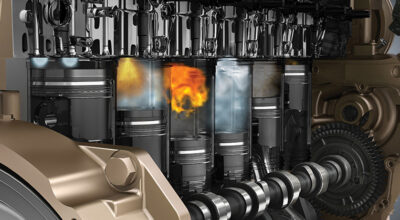

As the power behind the operation, the engine deserves to be treated with an abundance of care. If the engine goes, so too does all hope of productivity. To keep engine repairs to a minimum and productivity on track, equipment owners often look for top-of-the-line filters.

John Deere filters are designed to efficiently keep any debris that may be harmful to the engine, and its components, out. In this post, we’ve featured a few videos, each taking a closer look at the mechanical make-up of these filters, as they aim to protect engine integrity.

Why use John Deere Oil Filters?

Quality components and construction make John Deere oil filters a good choice for machines. Watch this video to learn more about the components (and their impacts), including:

- Rubber gaskets specifically designed for each application: Tighter seal than cork or plastic gaskets used by most other manufacturers

- Nut plate with rolled threads: Rolled threads prevent metal contamination vs. traditionally machined threads

- Crimped spiral center tube: Adds strength to prevent media from collapsing and allowing particles into the system

- Poly blend filter element: More durable than paper and guaranteed to meet John Deere specs for beta/micron rating and capacity

- Tight pleats and even media spacing: Ensure event filtration for better protection

- Additional pleat lock on larger filters: Ensures and maintains consistent and even media spacing

- Heavy-duty one-piece metal end caps: Stronger and better seal than cardboard or 2-piece lightweight metal

- Spring-designed for construction applications: Heavy-duty vs. standard automotive-strength spring

- Heavy-duty canister: Strong, longer fatigue life

Why are John Deere Air Filters Better?

Genuine John Deere filters defend against engine invading contaminants. They reduce engine wear by removing dust, dirt and other pollutants from intake air. Watch this video to get an inside look at Deere’s air filters. Some key components (and their impact) covered in this video include:

- Maximum media thickness: Captures more contaminants

- Poly bend media: Long life

- SuperLock pleated media features even pleat spacing: 99.98% efficiency and longer service intervals

- Additional pleat lock on larger filters: Ensures and maintains consistent and even media spacing

- Inner and outer metal liners: Strength and durability, and resistant to corrosion

- Thick urethane end caps: A strong, durable and leak resistant seal

Avoid downtime with John Deere Fuel Filters

Water is the number one enemy of fuel. John Deere fuel filters trap and repel water which can lead to poor performance and reliability. They’re matched to your machine for optimized fuel flow. Key takeaways from this video include:

- Tight seal between media and filter casing: Designed to keep dirty fuel from reaching the engine

- Coated media: Repels water and contaminants and keeps it from damaging fuel components

- Tight pleats/even media spacing with maximum surface area: Down to 5 microns in certain applications

- Hydrophobic filter elements: Media resists water vs. absorbing it

- Metal end caps: Stronger and more reliable, resists moisture

- Completely painted canisters: Painted canisters are designed to reduce corrosion, especially in drain valve area

Hopefully, these videos helped you better understand what makes John Deere filters some of the best available, so next time you hop aboard your agricultural equipment, you’ll start with confidence. If you enjoyed this post or want to read others, feel free to connect with us on Facebook!