This excerpt was originally posted on the John Deere, Straightforward Blog December 12, 2011. You can view the original post here.

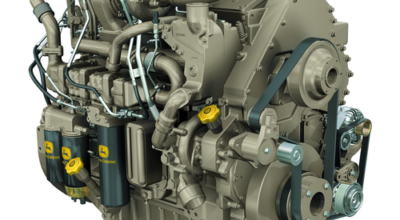

Engine technologies designed to meet U.S. EPA’s Interim Tier 4 (IT4) emission standards have been a hot topic here on the blog and across the industry. How has John Deere ensured its engine lineup is up to speed, while maintaining the top-notch reliability and efficiency you have come to expect?

The right technology, right now:

Simple. The single-fluid approach of the John Deere cooled EGR engine platform is simpler, more operator friendly and less complex to maintain than urea-based systems.

Fuel-efficient. John Deere not only leads with proven fuel economy technologies, but also offers a single-fluid solution for better total fluid economy. Our cooled EGR engines operate efficiently with ultra low-sulfur diesel as well as biodiesel blends, providing optimal performance and fuel-choice flexibility.

Field proven. John Deere was the first manufacturer to widely commercialize off-highway Tier 3/Stage III A cooled EGR diesel engines. Since 2005, we have used cooled EGR technology with proven reliability in agriculture, construction, and forestry applications.

Integrated. John Deere designs, manufactures and services the engine, drivetrain, exhaust filter, ECU, cooling, and other vehicle systems as part of a complete equipment package. This integrated process maximizes performance, operator convenience, fuel economy, and overall value to the customer.

Fully supported. Get service when and where you need it at any of our 4,000+ service locations worldwide. John Deere dealers are highly trained to help customers maintain their Interim Tier 4/Stage III B engines.

Interim Tier 4/Stage III B Technologies:

PowerTech PSX engines

93-448 kW (125-600 hp)

For ultimate performance in off-highway applications that take you up and down steep grades at high altitudes. Or when you simply want maximum transient response and low-speed torque. A PowerTech PSX 4.5L, 6.8L, 9.0L, or 13.5L engine is exactly what you need. Along with proven PowerTech Plus technology, all four displacements feature series turbochargers that improve performance and responsiveness.

PowerTech PVX engines

93 -224 kW (125-300 hp)

When you need unparalleled performance, PowerTech PVX 4.5L, 6.8L, or 9.0L engines are the perfect fit for your application. These displacements utilize our proven PowerTech Plus technology with variable geometry turbocharging (VGT) to improve performance and combustion efficiency, reduce emissions and increase fuel economy.

PowerTech PWX engines

63 – 91 kW (85 – 122 hp)

Equipment owners who want straightforward, cost-effective power rely on PowerTech PWX 4.5L engines. These compact engines blend proven cooled EGR technology with simple and reliable wastegated turbocharging to maintain transient response and peak torque in all operating conditions. Their 4-valve cylinder heads also provide excellent airflow for greater low-speed torque. Multiple rated speeds let you fine-tune your engine selection to reduce noise and fuel economy.

PowerTech M engines*

36 – 55 kW (48-74 hp)

The PowerTech M 2.4L and 4.5L engines are the simplest of the PowerTech family; these engines have 2-valve heads, fixed geometry turbochargers and mechanical fuel systems. PowerTech M engines are perfect for lower-horsepower applications. Their mechanical controls are simple to operate and maintain.

PowerTech E engines*

45-49 kW (60-66 hp)

The PowerTech E 2.4L engines also have 2-valve heads and fixed geometry turbochargers, but introduce full-authority electronic controls, more sophisticated fuel delivery and electronic unit pump fuel systems.

*The PowerTech M 2.4L and PowerTech E 2.4L engine lineups below 56 kW (75 hp) meet Interim Tier 4 and Stage III A emissions regulations and the PowerTech M 4.5L engine meets Interim Tier 4 emissions regulations without the addition of cooled EGR or an exhaust filter.