Combines are some of the biggest equipment investments that crop producers make. It’s essential to go into the used purchasing process with confidence and a clear understanding of what exactly it is that you’re looking for. Conduct ample research, ask questions, and inspect the equipment, to meet your operation’s needs.

While most farm equipment owners take very good care of their machines to maximize their lifespan, there are some things all used combine buying prospects should keep in mind. Here are some questions to ask (yourself and others) before making a purchase:

What size is right for my operation?

While a bigger combine with higher levels of production might seem great, it may not be the best option. You must consider how the combine will fit your operation. If you don’t have the resources in place to transport the grain once it has been harvested, you risk the combine sitting (full) waiting for a pickup. It’s always better to have a smaller machine producing an amount that can handled rather than a bigger machine sitting and waiting for the next available pickup. Before you go out to buy a used combine, always keep the size and capabilities of your overall operation in the back of your mind.

How many hours?

Review the total hours on the engine and on the separator. The engine hours will give you an idea of how long the combine has been running and the separator will give you an idea of how much work it has done. If the engine hours are much higher than the separator, you should be sure to check for drive train wear.

Is there visible wear and tear?

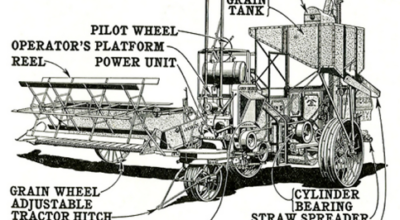

A combine should be judged by its cover. Remember to look for signs of wear on larger belts, chains and sprockets. Clear signs of wear could indicate poor maintenance by the previous owner, or overworking of the equipment. Be sure to also check the wear on the rotor/cylinder bars and concave.

How much can the header handle?

When buying a used combine, remember that a combine’s capacity should never be more than the gathering head can handle. The header is where the harvesting begins and the amount it can handle will determine how much grain can be successfully harvested and how much is wasted or damaged in the process.

How comfortable is it to operate?

Be sure to climb inside the combine to make sure the operator’s station has all the bells and whistles you’re looking for. The harvesting season calls for long days and many hours inside the combine, so be sure to ask about features such as storage, entertainment options, and seat comfort.

Can I start the combine?

When you’re inside the combine testing its comfort, if at all possible, get the combine started and running for a bit to see if there are any audible issues like grinding, screeching, or knocking. Any of these sounds could indicate an issue that could call for maintenance shortly after purchase.

Hopefully these questions will serve as a good reference when it comes time to purchase your first combine or another to add to the fleet.

If you enjoyed this post or want to read others, feel free to connect with us on Facebook, or Twitter!